Perfect Wood Joints with Dowelling Tools

Anyone who wants to quickly and easily make storage shelves for their basement usually resorts to a cordless screwdriver and the appropriate chipboard screws. What's perfectly adequate for the basement, however, isn't particularly suitable for the living area.

Visible screw heads on the sides of shelving don't look good. One option is to plug these holes with putty or filler – but that doesn't look very attractive either! For these cases, you need invisible wood joints.

Wood Joints: Three Powerful Tools for the Workshop

Dowel-Pin Joint

The most widely known "invisible" wood joint is the dowelled joint using dowel pins. This technique has gained such popularity because all that is required to make the joints is a power drill and the relevant wood drill bit. The dowel pins can be used to create corner, T-butt and edge-to-edge joints.

Applications of the Dowel Pin

Edge-to-edge joints

Dowel pins can also be used to extend the surface area of boards or to join them at right angles in order to create a frame.

A further excellent application for dowel pins is the reinforcement of picture frame mitres.

Corner and T-butt joints

In furniture making, virtually any cabinet can be built using these two joint types. Dowel pins are consequently ideally suited for building furniture.

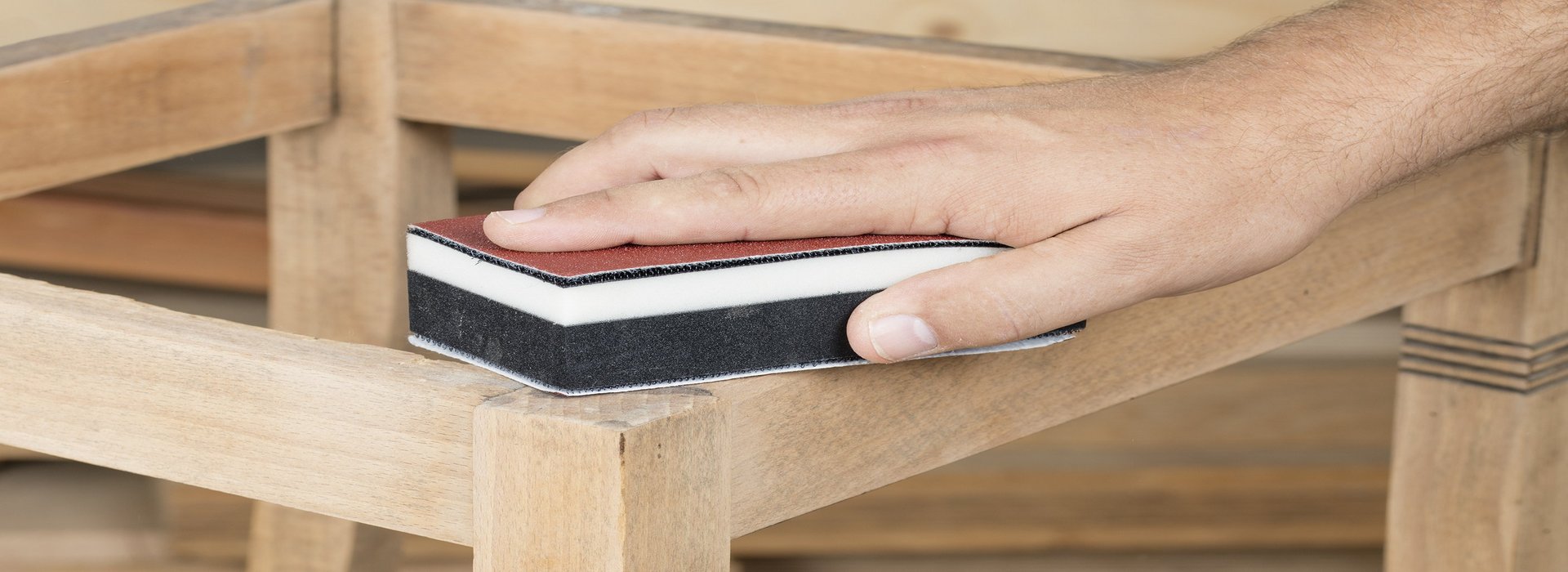

Be it chairs, tables or cabinets, dowel pins and all the joints employed here can be classified as either an L-shaped corner joint or as a T-butt joint.

Important: Dimensions for Dowelling

In the case of corner and T-butt joints, the holes in the wooden faces must only be drilled to a maximum depth of 2/3 of the wood thickness. The remaining dowel pin length, plus 2 to 3 mm of space for the glue, is drilled into the opposite side or the end face of the board. With this type of joint, two different drilling depths must therefore always be set with the aid of a depth stop.

For example: if the wood is 18 mm thick and the dowel pin is 40 mm long, the surface is drilled to a depth of 12 mm and the end face to a depth of 28 mm, plus a 2 mm space for the glue, in other words exactly 30 mm.

In the case of face joints, the dowel holes are drilled to half the dowel length plus around 2 mm space for glue in each board.

Wood Thickness and Dowel-Pin Diameter

The diameter of the dowel pin should measure between 2/5 and 3/5 of the wood thickness.

The table lists the most common wood thicknesses and the corresponding dowel-pin diameters.

| Wood thickness | dowel-pin diameter |

|---|---|

| 12 - 14 mm | 6 mm |

| 15 - 18 mm | 8 mm |

| 19 - 30 mm | 10 mm |

Biscuit Joint

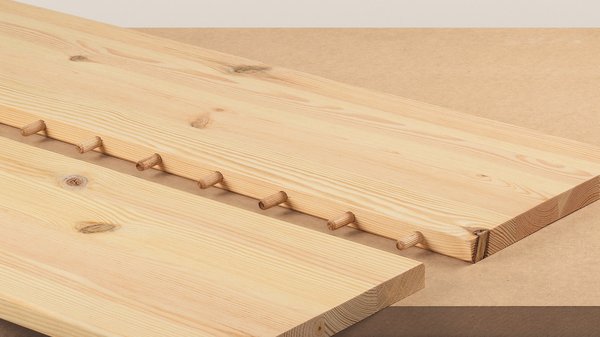

Less well-known are wood joints made using wooden "biscuits". They have a significant advantage over the dowel-pin joints: Contrary to dowel pins, the oval shape of the biscuit-shaped pieces of timber allows the joint to still be shifted in one direction.

Applications for Biscuits

Biscuit joints can be better and more easily adjusted than dowel-pin joints. The 4 mm slot makes it easier to accurately align the wooden parts when glueing them. Biscuit joints have an enormous load capacity and strength, because the glued area is significantly larger than that of a dowel pin and the biscuit swells when glue is applied.

To cut biscuit slots, you need a multi-wood jointer and a customary angle grinder.

The biscuit joint is ideal for furniture making, as it can be created quickly and with high precision. Everything from complicated installations underneath sloped roofs to basic corner joints for drawers can be made quickly and easily.